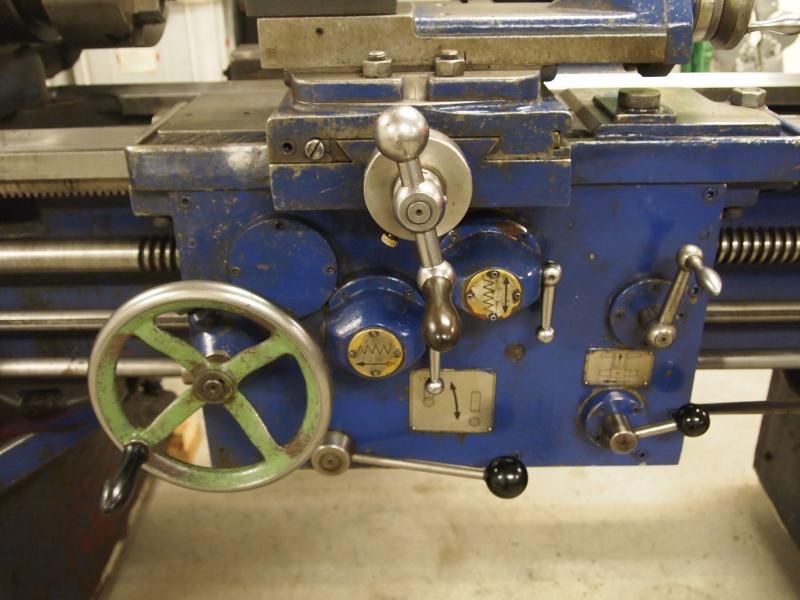

It's time to present my latest find, a Köping S8C 1960. Swedish high quality heavy iron!

I've been wanting one for years but they were not made in large numbers so they are not common on the market. Because this was the most complex machine the Köping factory ever did and therefor expensive at the time, most customers bought the basic S8S model instead.

I was lucky to find this one sitting in a garage 700 km away, the price was right so i bought it without having seen or tested it. Arranged the transport from home and after a week it landed in my home workshop without drama.

The seller also found a steady rest he did't know he had in the last minute, i also got a lot of tooling with it :D

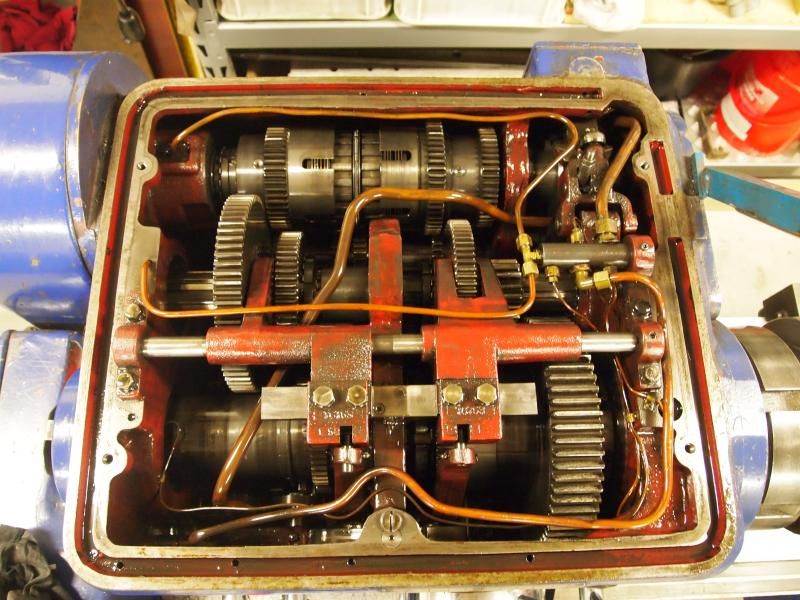

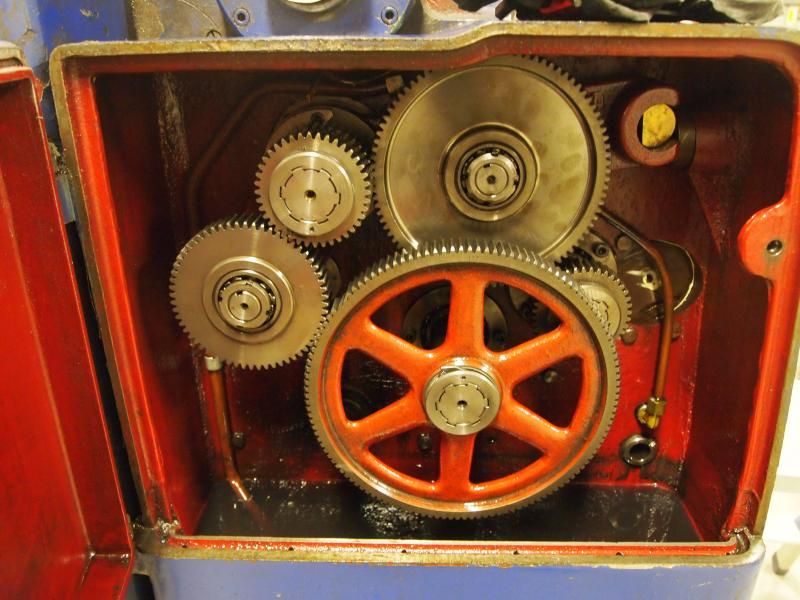

I have spent the last week cleaning and inspecting the lathe and beside the expected wear on a 53 year old lathe i've only found one damaged gear, it has 2 teeth missing ( large gear for metric threading ) luckily they can be bought new.

Here are some basic metric data.

Weight: 3400 kg

Height: 130 cm

Width: 130 cm

Lenght: 260 cm

Maximum workload 2200 kg !!!!!! :eek:

Power: 15 Kw/20 HP

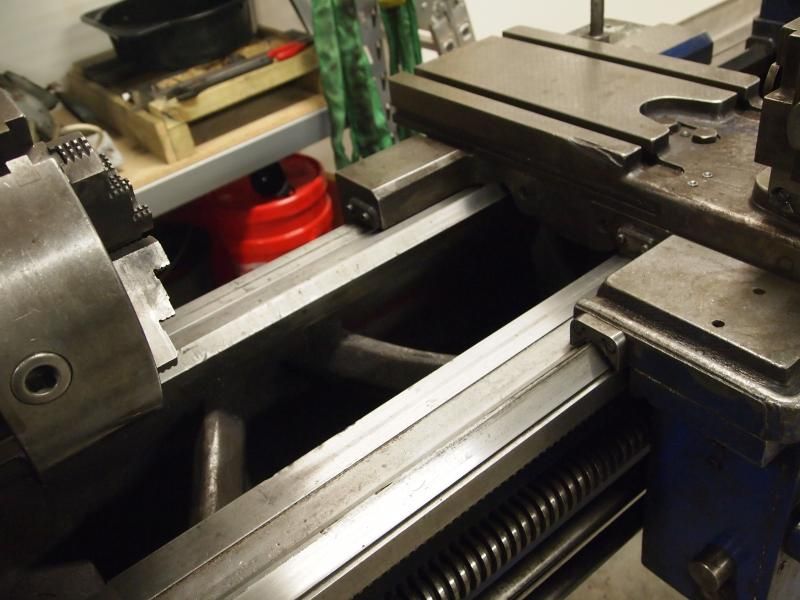

Distance between centers: 1000 mm

Swing: 8 inches or 200 mm (max diameter: 430 mm over bed)

1500 Rpm

And some pictures.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

I've been wanting one for years but they were not made in large numbers so they are not common on the market. Because this was the most complex machine the Köping factory ever did and therefor expensive at the time, most customers bought the basic S8S model instead.

I was lucky to find this one sitting in a garage 700 km away, the price was right so i bought it without having seen or tested it. Arranged the transport from home and after a week it landed in my home workshop without drama.

The seller also found a steady rest he did't know he had in the last minute, i also got a lot of tooling with it :D

I have spent the last week cleaning and inspecting the lathe and beside the expected wear on a 53 year old lathe i've only found one damaged gear, it has 2 teeth missing ( large gear for metric threading ) luckily they can be bought new.

Here are some basic metric data.

Weight: 3400 kg

Height: 130 cm

Width: 130 cm

Lenght: 260 cm

Maximum workload 2200 kg !!!!!! :eek:

Power: 15 Kw/20 HP

Distance between centers: 1000 mm

Swing: 8 inches or 200 mm (max diameter: 430 mm over bed)

1500 Rpm

And some pictures.